How to Source Injection Molding Services from China

Well, the major meeting has just concluded. your new product is a go, the timeline is aggressive, and funding is, to put it mildly, limited. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

You nod, of course. It seems sensible at first glance. Savings can be substantial. However, your brain is racing with concerns. You’ve heard the stories, haven’t you? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

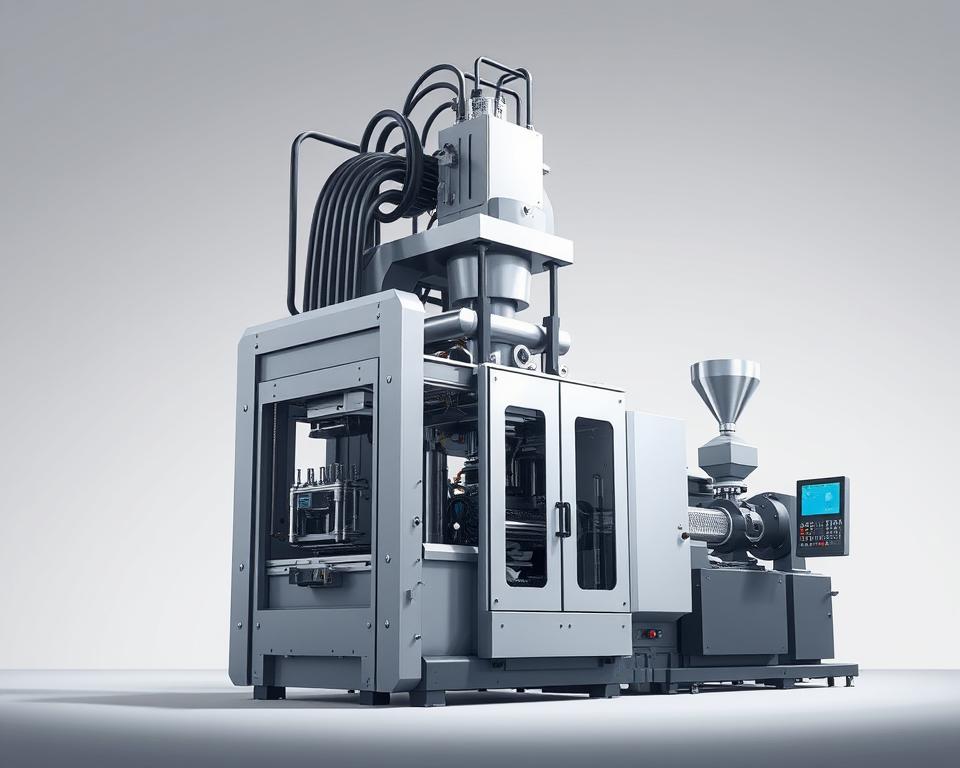

However, here’s the reality. Procuring China injection molding needn’t be a roll of the dice. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Disregard those scary tales. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You cannot expect overseas partners to interpret your unspoken requirements. It’s akin to asking someone to price-build “a structure” with no details. The replies will range from absurdly low to exorbitant, none of which help.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This becomes the bedrock of your sourcing project.

What belongs in your RFQ?

First, your 3D CAD files. They’re essential. Use standard formats such as STEP or IGS to ensure compatibility. This is the master blueprint for your part’s geometry.

Yet 3D models don’t cover everything. Include precise 2D engineering drawings. This is where you call out the stuff that a 3D model can’t communicate. Think tolerances, material grades, finish specs, and any feature-critical notes. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Then specify the material. Avoid generic terms like “Plastic.” Even “ABS” alone is too vague. Be explicit. If you need SABIC Cycolac MG38 in black, say exactly that. Why so detailed? Because there are thousands of plastic variations. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

They can offer alternatives, but you must provide the initial spec.

Don’t forget the commercial info. What is your Estimated Annual Usage (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

Finding the Right Supplier

Okay, your RFQ package is a work of art. now, who do you send it to? The internet has made the world smaller, but it’s also made it a lot noisier. Locating vendors is easy; vetting them is the real challenge.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Use them to build a shortlist, not the final list. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

Still, you must dig deeper. Perhaps hire a local sourcing specialist. They do cost extra. But a reputable agent brings pre-screened factories. They are your person on the ground, navigating the language and cultural barriers. On your first run, this is like insurance. Think of it as insurance for your project timeline.

Also consider trade fairs. If you can attend, shows such as Chinaplas transform sourcing. Nothing beats a face-to-face conversation. Hold samples, talk shop, and gauge professionalism firsthand. Plus, ask peers for referrals. Ask other project managers in your network. A solid referral can be more valuable than any ad.

Sorting the Contenders from the Pretenders

With your RFQ dispatched to dozens of firms, estimates roll in. Some prices will undercut logic, others will shock you. Your task is to filter them down to 2–3 credible finalists.

How to proceed? It involves both metrics and gut feel.

First, look at their communication. Is their turnaround swift and concise? Is their English good enough for complex technical discussions? But the key: do they probe your RFQ? The best firms will question and suggest. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” This is a massive green flag. You know they know their stuff. Anyone who simply agrees to all specs is a red flag.

Afterward, verify their technical arsenal. Get their tooling inventory. Review examples of parts akin to your design. A small-gear shop won’t cut it for a big housing.

Then comes the audit. Skipping this is a mistake. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They dispatch an on-site auditor for a day. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. It’s the best few hundred dollars you will ever spend on your project.

Converting Digital Designs into Molded Parts

After picking your vendor, you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Then comes the real action.

The first thing you should get back after sending your payment is a DFM report. DFM means Design for Manufacturability. This is your supplier’s formal feedback on your part design. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It’s a collaboration. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. Weeks on, you receive the thrilling “T1 samples shipped” notification. These represent the first trial parts. It’s your first real test.

T1 parts usually require adjustments. This is normal! You’ll find minor defects, off-spec dimensions, or finish issues. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold samples. This process might take a couple of rounds. Plan for this loop in your schedule.

Finally, a flawless part arrives. Dimensions, finish, and performance all check out. This becomes the “golden sample.” You sign off, and it serves as the master quality reference.

Final Steps to Mass Production

Landing the golden sample is huge, yet the project continues. Next up: mass manufacturing. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. Often, you hire a pre-shipment inspection service. Use a third-party inspector again. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. You receive a full report with images and measurements. Only after you approve this report do you authorize the shipment and send the final payment. This simple step prevents you from receiving a container full of scrap metal.

Finally, think about logistics. Understand the shipping terms, or Incoterms. Are you on FOB terms, where they load and you take over? Or EXW, where you handle everything from their gate? These choices hugely affect landed cost.

Overseas sourcing is a marathon. It relies on partnership-building. Treat them like a partner, not just a line item on a spreadsheet. Clear communication, mutual respect, and a solid process are your keys to success. No question, it’s demanding. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re ready.